As an experienced office chair manufacturer, we are extremely familiar with the materials and construction of any chair parts, so the office chair casters are no exception.

In this article, we will give you a comprehensive introduction to the types of office chair casters, their respective characteristics, and their specific components. Besides, there are some suggestions and hints on the selection. Hope it can help some office chair assembly manufacturers and office chair designers.

What Are Casters?

In certain circumstances like when the wheel is just one part of the caster, people use the terms “wheel” and “caster” interchangeably.

A caster is a device containing wheels that are attached to the bottom of large objects like furniture, trailers, trucks, etc. And it can move objects faster and easier.

Casters are used to pull and push objects instead of carrying them.

When Were Casters Invented?

The Development of Casters

When they were first invented, casters were mainly used for industrial purposes because they were very heavy. With their development, casters were made only with glass or leather to reduce sliding damage to wooden floors.

Casters today are still made from glass and leather. But there are many other materials, from plastic to iron, or anything in between, such as aluminum, stainless steel, rubber, or nylon. Now the design of casters also includes many functions like brakes, direction locks, shock absorption and high temperature resistance.

1. Rigid Casters

- The most basic type of casters

- Cannot rotate

- Designed to move objects along a straight line

- Usually used as the rear wheel of a shopping cart

2. Swivel Casters

- Rotation allows the object to rotate 360°

- Used as the front wheels of a shopping cart

3. Industrial Casters

- A kind of heavy duty casters

- Designed to transfer the objects up to 30,000 pounds

- The design can include rigid or swivel casters. For example, Dolly carts use industrial rigid casters

4. Braking and Locking Casters

- Any type of caster can include a special braking function, which is low cost and prevents the wheels from turning.

- It is usually a small lever that can be pulled to stop the movement of objects.

Advantages of Using Office Chair Casters

- Low cost

- Durable

- Make the movement of the chair more convenient

- Capacity of heavy weights

- Minimize possible injurious effects to the operator

- Various casters choices

The Production of Casters

We have distinguished the different types of office chair casters available, which can be made of many types of plastics and metals.

The split movable casters are mainly the caster bracket and the caster wheels. And they will correspond to the three major production process parts respectively.

(1) Injection molding part (movable wheel part)

Bake material > cutting > injection > out wheel > trimming > cooling > install bearing

(2) Hardware part (caster bracket part)

Blowing > Profiling > Drilling > Forming > Heat Treatment > Plating

(3) Assemble Casters

Assembling the movable casters and the caster brackets together will use some parts. After the quality inspection, the casters are packed, packed into boxes, put in storage, and sold out.

In short, caster production process is not only suitable for movable casters, but also for fixed casters. The difference lies in the design of the caster bracket and the caster structure. But the specific caster production process is basically the same.

It is worth noting that the quality inspection equipment of casters and the quality inspection process of casters are important aspects to ensure the quality of casters.

Tips For Choosing Office Chair Casters

There are things to consider when purchasing the right casters for your office chairs. Because the design and construction of casters will vary according to the following main factors:

- The way the chair being used

- The load-bearing capacity of the chair

- The type of floor the chair will roll on

These different considerations will determine the most suitable caster size, material and tread for you.

Smaller wheels bear more pressure during use and tend to be more difficult to roll.

While larger wheels are more suitable for frequent use and driving on long pile carpets. Inexpensively produced casters cannot effectively distribute weight evenly, which means they will wear out and are prone to fail.

Types of Office Chair Casters / Wheels

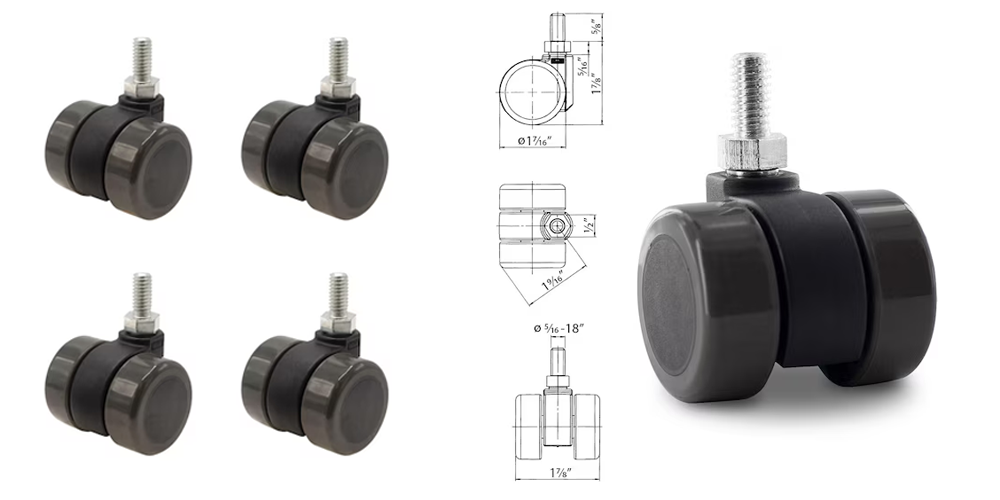

According to the number of wheels, the office chair casters usually can be divided into the following 2 types:

- Twin-wheel casters

- Single-wheel casters

Twin-Wheel Casters

Twin-wheel casters are probably the most commonly used casters in office chairs.

The double-wheel design creates a wider surface for more efficient weight distribution. Thereby extending the life of the casters and preventing any damage to the floor.

The double wheels are also special. Because they can both roll and rotate, change direction easily and quickly, and also keep stable.

Single-Wheel Casters

Single-wheel casters tend to be stronger than double-wheel casters because of their stronger structure and fewer moving parts that may fail.

For these reasons, they are generally used in more industrial applications, and the two-wheel option is most suitable for office furniture.

Then, according to the different materials and the functions, there are 3 types of office chair casters including:

- Carpet casters

- Hard surface casters

- Reverse locking casters

And they are usually made of some kind of plastic with a hood.

These models are made of materials that can safely roll on hardwood floors without causing any damage. And there are more other advantages of PU casters.

After the weight is removed, it will be easy for the chair to roll and move around the room.

Floor Glides

While the use of casters is to ensure that the chair can move easily, floor glides (contrary to the name implies) is used to hold the chair in place.

Glides usually have a similar stem mounting system. Differently, they are composed of a metal bottom, which makes the chair stable and ensures that it will not slip out of place easily.

In many cases, the floor glides can also be adjusted in height to help deal with uneven surfaces.

The elastomers, nylon, steel and other materials can be the elements of the actual wheels of the casters.

Sometimes the wheel is actually a ball that can roll in any direction.

Office chairs usually use a plastic or rubber material. While more industrial, heavy-duty casters tend to use metal materials.

Office Chair Caster Stem

Generally, stems are used instead of mounting plates to connect the wheels to the legs. Insert the stem into the chair leg and shell to help hold it firmly in place.

Office Chair Caster Bushing

This component helps casters to run smoothly and provides easy sliding movement.

Caster maintenance can include regular cleaning and lubrication of these bearings.

Office Chair Caster Hood

Some casters come with a hood that serves as a mudguard to hide all dirt and debris collected when the it rolls.

Although this is a convenient addition, it does not actually contribute to the function of the casters.

Types of Office Chair Caster Stem

Office Chair Caster Grip Ring

This type of caster is characterized by a stem with a groove at the top of that, which is covered with a split steel ring, also called a grip ring.

When the stem and ring are inserted into the leg socket, the ring exerts outward tension on the rubber housing, thereby holding the stem in place.

Office Chair Caster Grip Neck

The grip neck stem has a wide base and a narrower head. After the stem installing, the socket expands enough to allow the head to pass and firmly grasp the wider part of the stem.

This can effectively lock the stem in place.

Office Caster Threaded Stem

A threaded stem is essentially a screw that can be screwed into a socket and can be reinforced with nuts and washers.

Office Chair Caster Top Plate

It’s a plate bolted to the bottom of the chair legs and fixing the casters in place.

These are more common in file cabinets and other types of office furniture.

While the stem system is the indispensable component for most office chairs to be connected with casters, other heavy duty casters are installed with top plate brackets.

In essential, the wheels are held in place with yokes and axles, and screwed to the bottom of the chair or trolley through the top plate mount.

How to Measure Grip Ring Stem?

When you order replacement casters, taking accurate measurements is very important. Because it can ensure that you get the right product the first time with no payment of any return or handling fees.

When measuring a grip ring stem, you need to find the diameter of the stem head and base.

A simple ruler can be placed on the top of the steps to calculate the diameter.

Most grip ring stem heads are 5/16″ in diameter, although people tend to misread the scale and order 3/8″ models.

To confirm your measurements, you can compare the diameter with drill bits of different sizes. You can also try to install a 5/16-inch wrench around the stem head. The stem base is usually 7/16” or 3/8”.

The wheels ranging from 2 inches to 2.5 inches have become standard for most office chairs.

Although this is certainly a sufficient size, there are still some benefits to using larger wheels and choosing wheels of at least 3 inches.

As you might imagine, larger wheels have less resistance when rolling and can overcome obstacles, including plush carpets, more easily. Larger casters provide more durability and versatility, which means you don’t have to worry about having to replace the casters.

Although the world of casters is very various, this guide covers many of the most popular and commonly used casters.